PP FIBRILLATEDJUTE REPLACEMENT YARN

WHAT IS

THE JUTE REPLACEMENT

WEFT YARN?

- Very low shrinkage

- High strength

- High performance

- Fibrillated

USAGE AND FUNCTIONS

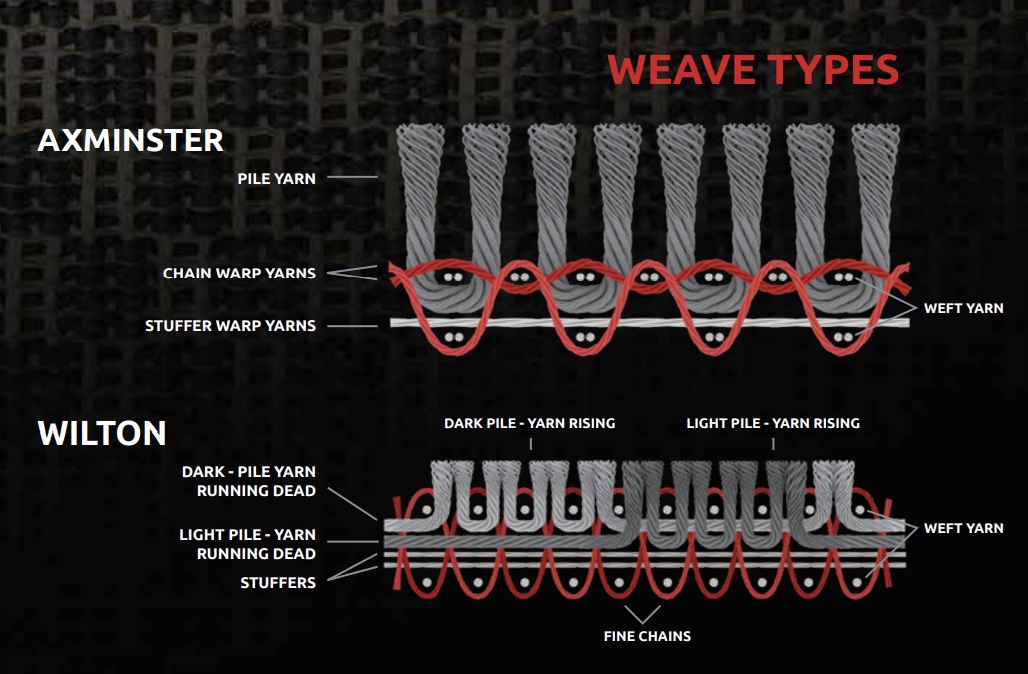

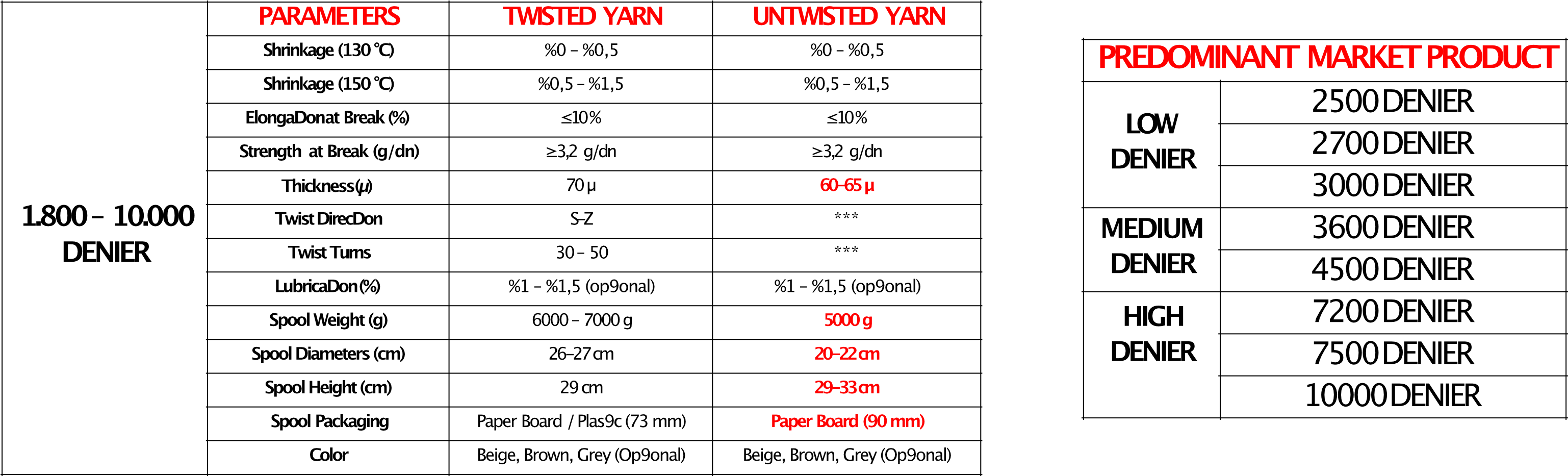

Flament Packaging produces twisted and untwisted polypropylene jute replacement yarns that can be used in carpet making. Some of the main driving factors behind the replacement of natural fibers by fibrillated PP replacement yarns are due to fluctuations in price, quality and availability of natural fibers such as jute and sisal. It has advantages over natural fibres, such as consistent and clean production and conversion, lower risk of contamination by foreign fibres, significant weight savings, a higher strength-to-weight ratio and improved mechanical properties.

FEATURES AND BENEFITS

Flament Packaging polypropylene replacement jute yarns are made to strictly controlled shrinkage specifications and allow the carpet to be processed through the latex finishing process without fear of shrinkage, thus increasing efficiency. Since the threads are more uniform than traditional jute threads; a uniform pile height is easier to achieve, resulting in fewer pile yarn cuts The homogeneity of the yarn ensures smooth running and reduces downtime caused by yarn breaks.

- Provides protection against mold and fungus formation, Resistant to acids and alkalis.

- Fibrile PP Yarn ensures that outdoor carpets last a long time as a result of its UV treatment.

- Twisted and untwisted applications are available.

TECHNICAL SPECIFICATIONS

*Single color production is available.

*Single color production is available.